![]() I’ve been finding media coverage of operation ‘Top Kill’ – BP’s latest attempt to seal the Deepwater Horizon well leak in the Gulf of Mexico – rather confusing, so I’ve attempted to think through what pumping mud into the well is trying to achieve, and what we should expect to see if it is succeeding. I freely admit I’m not an expert, so I welcome any corrections and clarifications from people who are in the comments.

I’ve been finding media coverage of operation ‘Top Kill’ – BP’s latest attempt to seal the Deepwater Horizon well leak in the Gulf of Mexico – rather confusing, so I’ve attempted to think through what pumping mud into the well is trying to achieve, and what we should expect to see if it is succeeding. I freely admit I’m not an expert, so I welcome any corrections and clarifications from people who are in the comments.

Update 30th June: ‘Top Kill’ has been abandoned – it seems that they just couldn’t get mud into the well fast enough.

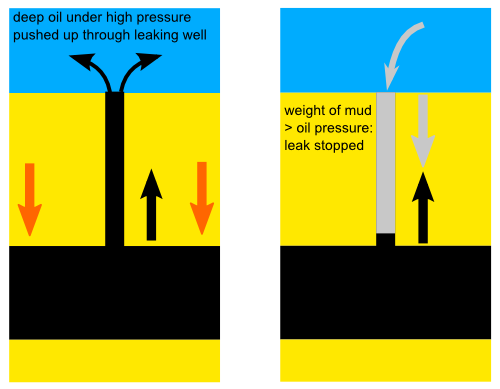

The oil in the formation that the Deepwater Horizon drilled into is under high pressure: the high confining pressure provided by more than 5km of overlying rock has allowed high hydrostatic pressures to build up. Now that there is a weak point (the well) this pressure is pushing the oil upwards to the sea bed and out into the ocean (left in the figure below). To stop this, BP is trying to inject dense, heavy drilling mud into the well. If they can pump enough mud into the well, its weight will exert a downward pressure that will cancel out the upward pressure pushing the oil up the borehole, and no more fluid will escape (right in the figure below). At this point, the well can be permanently sealed by concreting it over.

Latest footage from the sea floor indicates we’re not at that point yet.

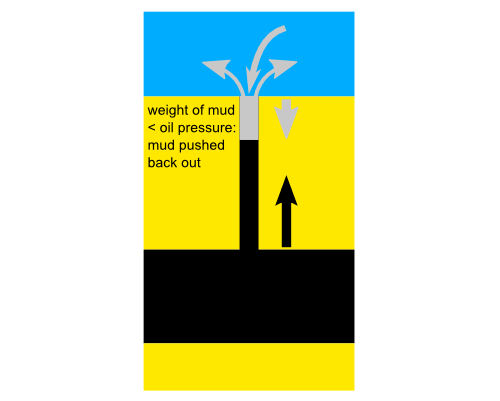

It looks like the stuff currently emerging from the leaks is probably drilling mud, rather than oil and gas – or at least mud mixed in with the oil and gas. As the mud starts to be injected into the well, the oil pushes back against it, and there is not yet enough mud at the top of the borehole for its cumulative weight to counteract the upwards pressure. The mud is therefore being forced back out of the well again.

So, if the operation continues according to plan, what should we expect to see? Assuming that mud can be pumped into the well at a faster rate than it is pushed back out again – and BP has enough drilling mud on hand to continue the operation – it will gradually push further and further down the well against the oil. More mud in the well means more weight for the oil to push against, which should reduce the amount of mud that can be pushed back out of the well. So the volume of leaking fluid should theoretically be decreasing as pumping continues. Lets hope so.

Comments (36)